In high-risk vehicle zones with harsh conditions like coastal areas and industrial centers, specialized corrosion protection procedures are essential. These involve using galvanised steel or protective coatings, regular inspections, quick repairs, painting, undercoatings, and rust inhibitors to prevent damage and save on costly repairs. Corrosion protection isn't just about aesthetics but also passenger safety and reducing future repairs. Experts implement multi-faceted approaches including thorough inspections, surface treatments, washing, timely repairs, and high-quality paint solutions.

In the automotive sector, understanding high-risk vehicle zones is paramount for ensuring optimal performance and safety. These areas, often exposed to harsh environments, require enhanced corrosion protection procedures to prevent metal degradation. This article delves into the intricacies of identifying these zones, exploring essential corrosion protection methods tailored to their unique challenges. We’ll also guide you through implementing and maintaining effective prevention strategies to safeguard vehicles against corrosive forces.

- Understanding High-Risk Vehicle Zones

- Essential Corrosion Protection Methods

- Implementing and Maintaining Prevention Strategies

Understanding High-Risk Vehicle Zones

High-risk vehicle zones refer to areas where vehicles are frequently exposed to harsh environmental conditions or corrosive elements that can accelerate metal deterioration and damage. These zones often include coastal regions, industrial hubs, and areas with high humidity levels. Understanding these zones is crucial when implementing effective corrosion protection procedures. Vehicles operating in such environments require specialized care to safeguard against rust and corrosion, which can lead to costly repairs, including fender repair, car body repair, and auto glass replacement.

By identifying and categorizing high-risk zones, vehicle owners and maintenance professionals can tailor their corrosion protection strategies accordingly. This involves selecting suitable materials that offer enhanced resistance, such as galvanised steel or specialized coatings designed to combat corrosive substances. Regular inspections and prompt repairs for any signs of damage are also vital components of a comprehensive corrosion protection plan.

Essential Corrosion Protection Methods

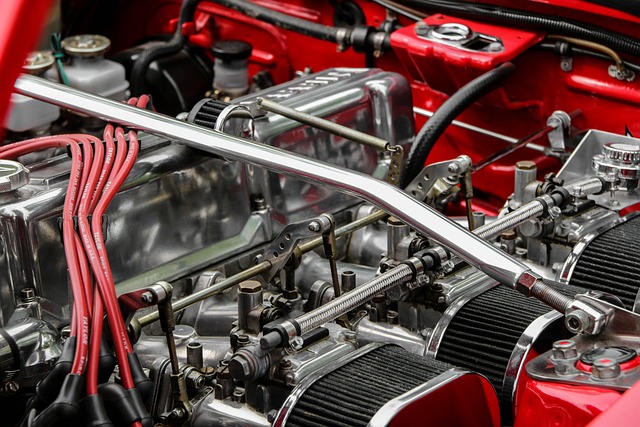

In the quest for durable and reliable vehicles, corrosion protection procedures are non-negotiable, especially in high-risk zones. These methods form a robust defense against the element, preventing metal degradation that could compromise structural integrity. Among essential corrosion protection techniques is regular painting and coating of vehicle surfaces, creating an impenetrable barrier against moisture, road salt, and other corrosive substances. This step is crucial for both aesthetic preservation and the longevity of various components within the car body.

Additionally, the application of undercoatings and rust inhibitors further strengthens corrosion defense. Such products are designed to penetrate existing pinholes and minor cracks, filling them before they expand into larger issues. Regular maintenance checks that include inspecting these areas during routine car repair services become vital in identifying potential problems early on. For vehicles undergoing automotive collision repair or car restoration, prioritizing comprehensive corrosion protection is not just about aesthetics; it’s about ensuring safety and minimizing future repairs by creating an impenetrable shield against the environmental aggressors that can hasten metal decay.

Implementing and Maintaining Prevention Strategies

Implementing corrosion protection procedures is a proactive step towards safeguarding high-risk vehicle zones from the relentless damage caused by corrosion. This involves a multi-faceted approach, beginning with thorough inspections to identify vulnerable areas. Once identified, targeted treatments like surface priming and sealing can create a protective barrier against moisture intrusion. Regular washing and degreasing are also essential auto maintenance practices that remove salt and other corrosive substances adhering to the car’s exterior.

Maintaining these corrosion protection strategies requires consistent vigilance and timely intervention. Repairs, such as fixing leaks or addressing dents promptly, prevent water seepage and subsequent rust formation. Additionally, applying regular coats of high-quality car paint repair solutions reinforces the protective layer, ensuring the vehicle remains in optimal condition. Automotive collision repair experts play a crucial role here, offering specialized services to mend structural damage that could compromise corrosion protection efforts.

In light of the above, implementing robust corrosion protection procedures is paramount for high-risk vehicle zones. By understanding these areas and employing essential methods like regular inspections, optimal storage practices, and suitable coatings, fleet managers can significantly extend vehicle lifespans. Consistent maintenance and proactive strategies are key to mitigating corrosion damage, ensuring safe and efficient transportation in challenging environments. Adopting these corrosion protection procedures is a game-changer for maintaining a robust fleet.